Like many countries, Japan is increasingly concerned with sustainability and environmentally friendly solutions to the major challenges facing the country, and the world as a whole. As part of its ongoing efforts to address these challenges, there have been ongoing efforts in Fukushima prefecture to develop and promote businesses that offer innovative solutions to serious problems, and one of these companies is Rice Resin, a company that produces bioplastics.

What is Rice Resin?

Founded in 2021 in Namie city, Fukushima, Rice Resin produces a number of products using rice that would typically be produced using less environmentally sustainable materials, such as plastic.

On November 21, Rice Resin and its representative, Shohei Iida, were kind enough to welcome JoynTokyo as part of a group trip organized by JTB, one of Japan’s foremost foremost travel agencies, examining exciting new businesses in Fukushima prefecture. Rice Resin was chosen specifically for its rapid and impressive success in promoting environmental solutions that not only help protect the environment, but also help regenerate the Fukushima area as a whole after the 2011 catastrophe.

How Does it Work?

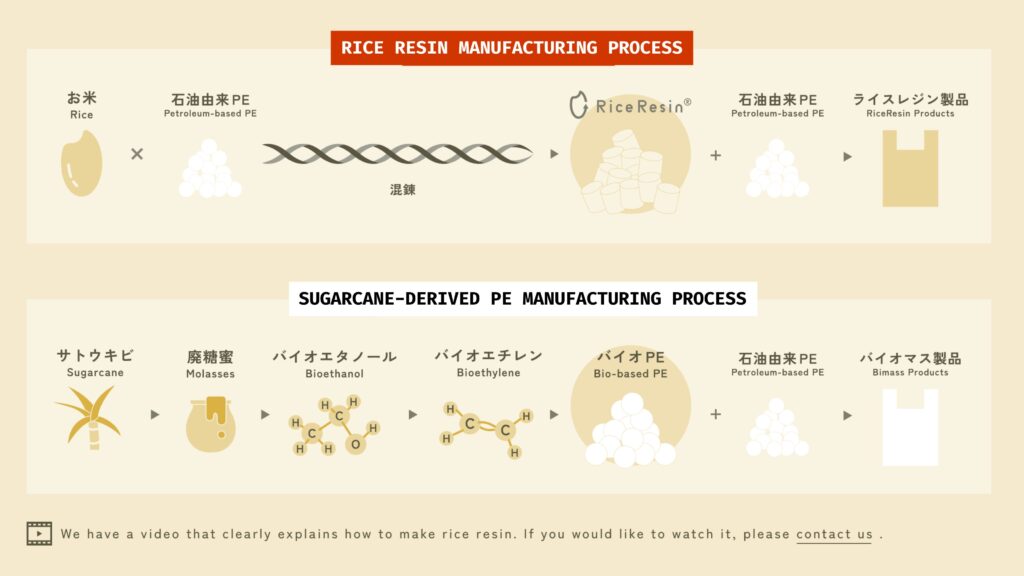

The process to create plastic-like products using rice is surprisingly simple, and even a small factory can produce a significant amount of rice resin to be used in the various products that can be produced, which we will discuss in more detail below.

Rice is, essentially, processed and cleaned before being compressed and bound up as an almost-udon noodle-esque series of strings that will later be used in a variety of items that would typically require 100% petroleum-based plastic.

Environmental Benefits

“There are two kinds of rice resin that we make,” Iida explained. The first is R50, which is used in the creation of polyethylene, and the other is R70, used for polypropylene.” As the names suggest, R50 is a plastic that uses rice for 50% of its materials, while R70 is 70% composed of rice.

While, at present, it needs to be augmented in order to make the products viable for use, Rice Resin’s process nevertheless reduces CO2 emissions by up to 57%, when compared with traditional plastics.

Safety

Furthermore, because the products are made with rice, they are safer than typical plastics if there are any minor accidents.

“We made toys that are made with over 50% rice, so if a child licks the toy, it’s a lot safer for the child than regular plastic,” Iida explained.

Start Your Own Japan Journey With Expert Guidance

Most people never make it to Japan because the start is confusing and tiring. Wrong visa route. Underestimated budget. Months lost to confusion.

Get personalized support for your new life in Japan.

Book Your FREE Consultation✓ 500+ Bookings ✓ English-speaking Relocation Support Experts

Why Fukushima?

With all of these potential benefits, why did Rice Resin decide to open in Fukushima prefecture?

Financial Incentives

Part of the reason that Rice Resin — and other high-tech and innovative companes — have chosen Fukushima is that, following the 2011 earthquake and tsunami, many areas of the prefecture, including Namie city, were forced to be abandoned. While many areas of rural Japan are facing depopulation challenges, Fukushima’s revival is a symbol of the ability of the people of the prefecture and the country to overcome significant difficulties.

To this end, Fukushima itself and Japan at the national level have offered a series of grants, lot interest loans, and help in business organization and founding on the condition that the companies remain in, and hire from, Fukushima.

Fukushima’s Rice

Indeed, Fukushima is actually the perfect place for Rice Resin to set-up, for agricultural-related reasons. Firstly, whether rightly or wrongly, Fukushima still has something of an image problem when it comes to its products, especially food. As such, even as the price of rice has increased over the past 18 months, very few farmers are using Fukushima’s fertile yet empty farmland.

Because the rice used by Rice Resin does no necessarily need to be edible, this means that rice not typically grown for human consumption can be used. Trepidation over the quality of Fukushima’s rice therefore becomes a non-issue, and the wide open land that can be used to grow rice to create sustainable products to be used all over Japan.

More, while the government keeps reserves of rice for emergencies, even this will eventually go bad and become inedible: however, this is not an issue for Rice Resin, and so what would have been food waste will instead be put to good use for the people of Japan.

What Products are Available?

Despite being a realtively new company, goods made using Rice Resin’s bioplastics can be found all over Japan.

Original Goods

Rice Resin’s bioplastics can be found in a number of reusable, sustainably made commodities. These include kitchenware, such as mugs, plates, and cutlery, and toys for young children, as well as the challenging Quemoe 30 puzzle.

It also provides materials for a number of novelty items, such as Japanese fans made with Rice Resin’s materials, in addition to pens used by the Japanese Post Office and pin badges.

Disposable Goods

Of course, one of the major issues with normal plastic is that its use for disposable commodities means that a lot of CO2 is expended — and often wasted — on things that have no secondary use purpose. Luckily, Rice Resin can also replace these fully-plastic goods, and has begun doing so.

Some of its most popular disposable goods include shopping bags, which retain the charm of rice with a scent and sensation reminiscent of their origins. They we used recently by the Fuji Rock Festival for their attendees. It has also been used for single-use cutlery in national burger chain Mos Burger, and disposable toothbrushes, the likes of which are often found in hotels.

Rice Resin has emerged not only as one of the most interesting and versatile innovative companies to be founded in Fukushima in the aftermath of the 2011 disaster, but is already making massive waves in Japan, turning inedible rice into a source of bioplastic. I’ll be making sure to use my Rice Resin spoon for my next homemade Japanese curry dinner… though it may seem a little odd to eat rice using a rice spoon!